Appearance

Introduction

This section provides a sample blueprint to create a door job from scratch.

Tools

- Laptop, PC, or Operator Station with KvalCAM installed.

- EFX DL-NCX loaded

NOTE

Although we're using an EFX line in this example each Feature may be adapted to use on different machines.

In most cases completed door files are created beforehand and are stored in the KavlCAM Libraries. Door Jobs are then created by combining each file. This is an excercise to highlight the buildings blocks of creating a Door Job file.

Getting Started

In the next section we'll be manually creating a Door Job following a blueprint sent from the ABC Company. This is a heavy-duty architectural door that will be processed on the EFX/DL-NCX line.

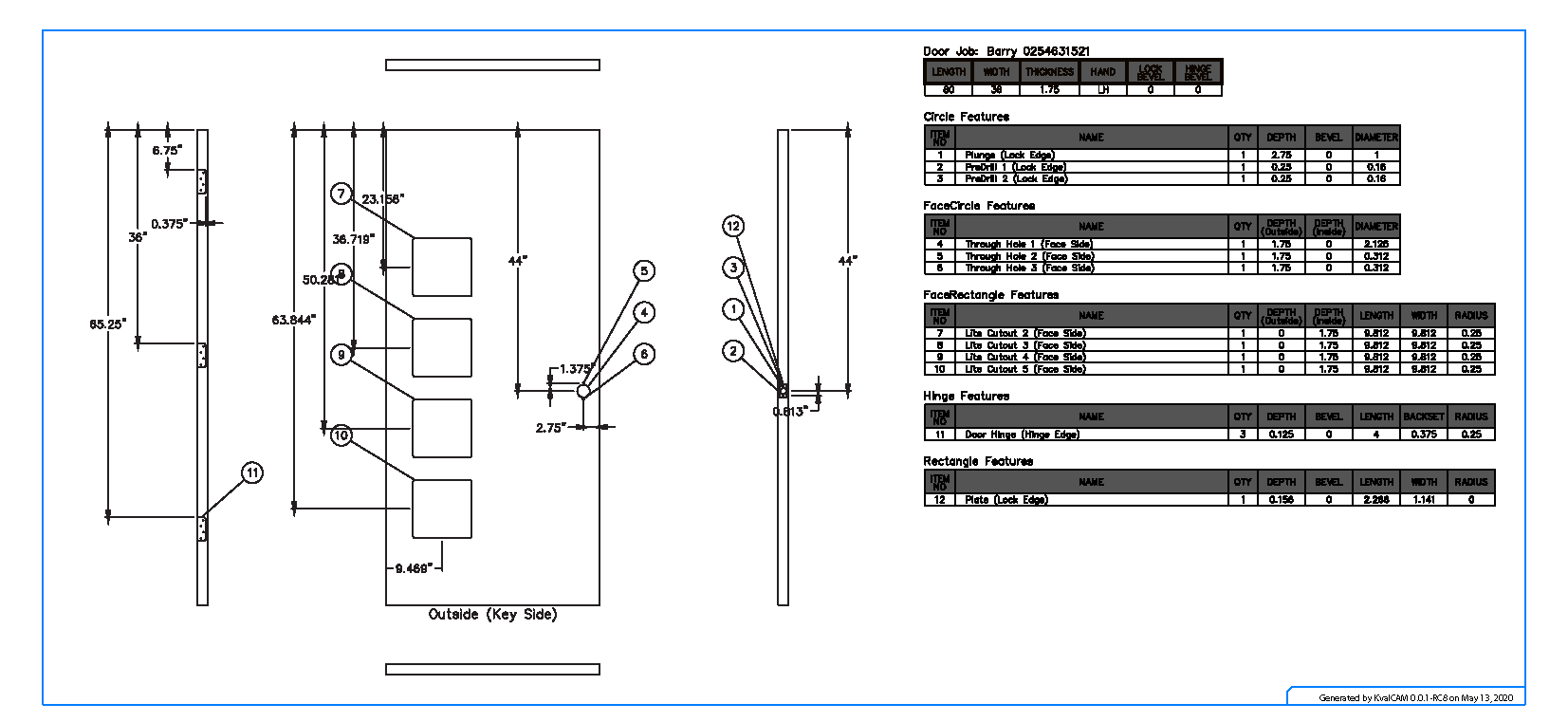

Blueprint

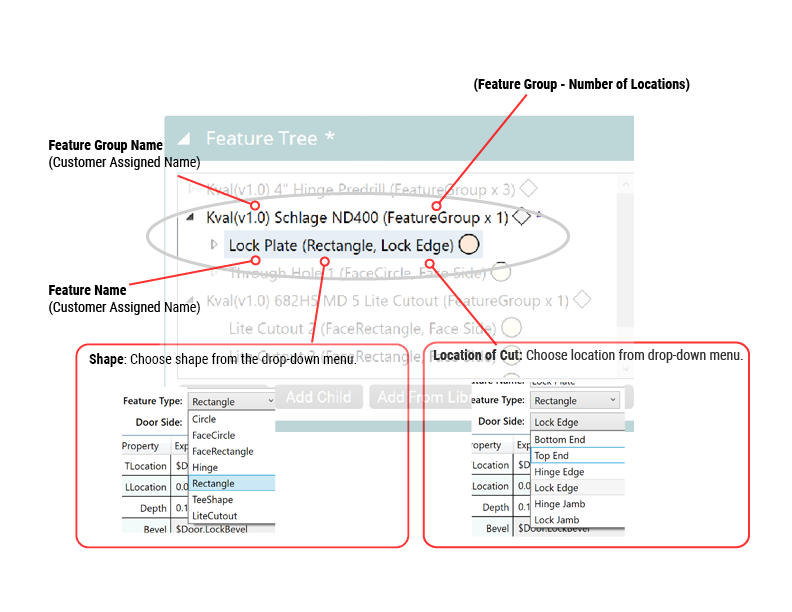

Feature Groups

Feature Groups can be thought as a container that holds the cut routines to be performed on the door. These cuts are identified as Children (Templates).

From the Feature Library, Feature Groups can be pulled into different Door Jobs. Templates can be altered or cloned as new templates giving immense versatility to create a Door Job.

Using the sample blueprint, the door cut routines can be separated into three Feature Groups. Under each Feature Group are children (Features) that represent aspects of the cut. Create the feature groups below:

- Lock Feature Group

- Hinge Feature Group

- Door Lite Feature Group

Breakdown of a Feature Group and Features

Feature Groups and Features resemble an outline.

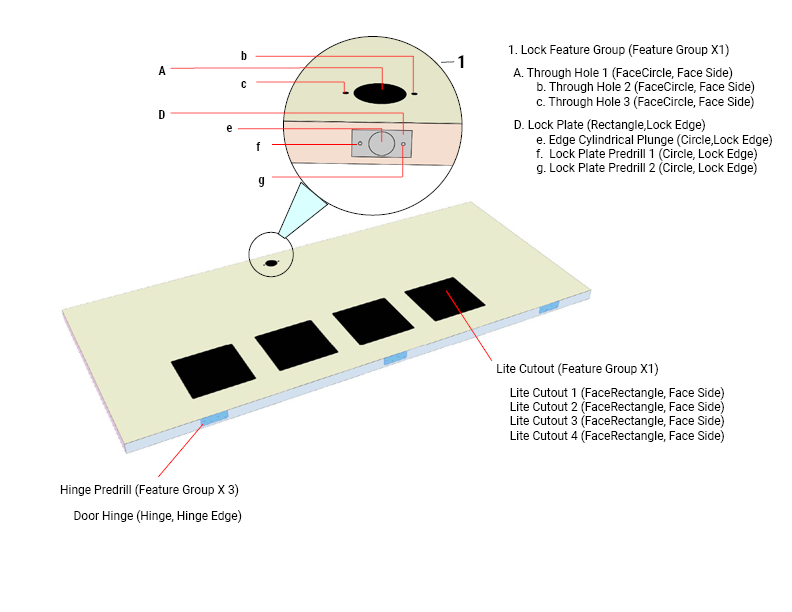

3D Preview

In the drawing below, the three Feature Groups are listed . (Lock Feature Group, Lite Cutout, and the Hinge Predrill)

TIP

Look at the Lite Feature Group and the Hinge Predrill Group. Both use repeated cuts: the Hinge Predrill repeats the cut at Feature Group level, assigning different locations, and the Lite Cutout repeats the cut as children with different locations.

Both ways are correct, use the method that suits your factory's process.